Our Stories

The greatest measure of our team’s success is the success and business growth our clients see as a result of implementing our solutions. When we help a Pennsylvania company succeed, we create revenue and jobs which, in turn, helps all of Pennsylvania. Please enjoy these examples of our team helping clients more effectively manage their energy and technical resources, creating unique real-world opportunities for student engagement, and benefiting Pennsylvania in a number of measurable ways.

PennTAP Conducts Boiler Energy Assessment for Pennsylvania Food Processing Facility

PennTAP worked with a local manufacturer to help them reduce their energy use and costs and increase the efficiency of their energy systems. The cost savings from these system recommendations is estimated to be $208,000/year and equates to energy savings of 9.652 million British Thermal Units per year.

Building Re-Tuning Drives Savings in Hampton Township

PennTAP conducted a Building Re-Tuning (BRT) walk-through of the Township of Hampton’s police station and reviewed the Township’s monthly electric and natural gas consumption statistics. PennTAP’s assessment led to extensive repairs and renovations and ultimately energy and cost savings for the Township of Hampton.

Preventing Pollution and Reducing Resource Use at Hazeltine Maple Farm

PennTAP worked with a maple syrup producer to upgrade their production process by adding an energy-efficient reverse osmosis machine which helped them save costs and reduce direct air emissions.

PennTAP Helps Tech Cast Realize Nearly $10,000 in Annual Savings

PennTAP completed an energy audit at a Pennsylvania foundry recommending an update to upgrade their lighting, repair compressed air leaks, and install insulation resulting in significant cost savings and increased efficiency.

More than 100 Participate in Building Re-Tuning Workshop

PennTAP’s Energy and Environment Team offered training and education to help those involved with building operations learn how to run facilities more efficiently and reduce operating costs.

Energy Assessment Yields Benefits for Mitcheltree

PennTAP analysis determined that Mitcheltree could save up to 1,255 MMBTU per year by upgrading lighting to LEDs, installing new LEDs, and installing a high-efficiency natural gas heating system. Mitcheltree received a grant of more than $13,500 for its $55,000 project to upgrade the heating system to natural gas.

Boiler Assessment Leads to Projected $25,000 Savings

PennTAP visited the Castle Co-Packers facility to assess boiler combustion efficiency, evaluate heat loss from uninsulated piping, and find opportunities to recover waste heat. Based on PennTAP recommendations, Castle Co-Packers would be able to save $25,000 per year on natural gas costs.

Lighting Assessment Shows Significant Savings Potential in Dauphin Precision Tool’s Facility

PennTAP completed a lighting assessment and compressed air leak check at Dauphin Precision Tool’s two facilities. The assessment shows that Dauphin Precision Tool will see an annual savings of $47,000 by upgrading the lighting system to LEDs and fixing the compressed air leaks.

Penn-Troy Projects Savings from LED System Upgrades

PennTAP helped Penn-Troy apply for the Rural Energy for America Program (REAP) grant and upgrade their facility to an LED lighting system. Penn-Troy is expected to save 187 million British Thermal Units (BTU) per year, equivalent to $7,000 per year, as a result of the upgrade.

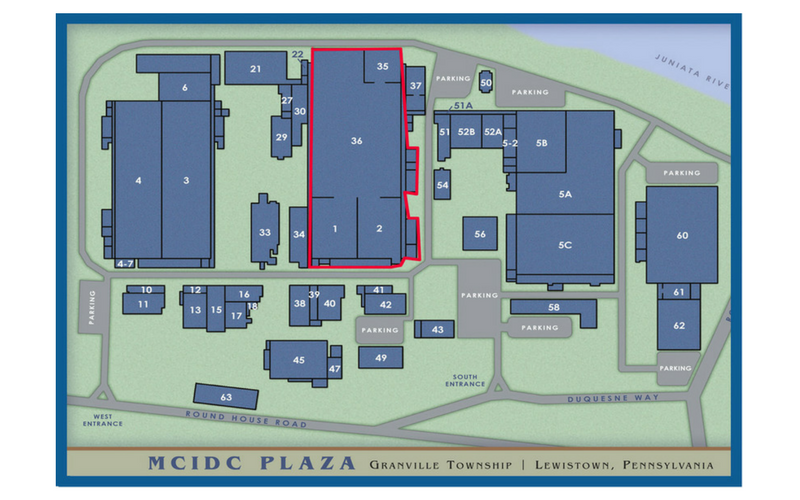

Lighting Assessment Yields Potential Savings of $33,000 for Mifflin County Nonprofit

The Mifflin County Industrial Development Corporation (MCIDC) facility consists of multiple buildings leased by various businesses. An analysis of five of those buildings by a team of PennTap technical advisors and students determined that upgrading the lighting in those five buildings could save 164 tons of greenhouse emissions (or approximately 387,000 kWh of electricity) annually, equaling a savings of $33,000 per year.